Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Plan It, Track It, Manage It with Plex

Manage complexity with efficient scheduling and a control panel that delivers real-time visibility all the way to your shop floor equipment. (5:59)

Video Transcription

Plex production management operationalizes your processes for increased productivity with an intuitive Control Panel that connects you to your equipment through shop floor integration. Plex Production Management can control production by enforcing standard processes. The intuitive control panel is a common, unified production hub that monitors and controls inventory, quality, and production in real time. And shop floor integration tools help connect to, and collect data coming from, your automation equipment. Plex production management connects your business with your entire plant floor – even wirelessly!

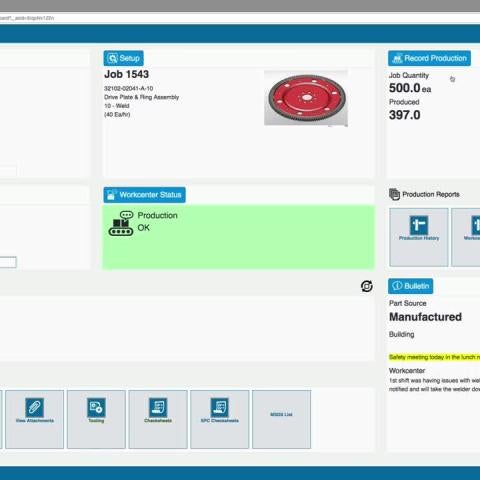

Let’s start with an overhead view of a production facility. Anywhere you see a magnifying glass you can see a pre-defined list of options. If you use this screen a lot, you may want to add it as a favorite using the familiar “star” icon. This is a real-time, configurable view of the status of the entire production floor. Easy to see, color-coded graphics show the status of production, quality, tooling, and maintenance alerts. And all this rich visual information is available anywhere, anytime on your Internet-connected smartphone or tablet. With direct connectivity to shop floor PLCs you capture machine data in real-time – or at the “manufacturing moment” - to eliminate errors and increase traceability. Notice that Welder 1 has just changed from Green to Red. With a simple click, you can drill down into the details to see what the problem is. Let’s take a closer look. By clicking on the workcenter we access the control panel where we see that a robot fault has caused the job to stop. This is the control panel that acts as the production hub for Plex where operators focus their efforts. At the control panel, data is delivered to and collected by the shop floor operator. It is highly configurable, touch-screen enabled, and easy to use by anyone. And of course, the control panel is available in multiple languages. All operators receive real-time critical data such as up-to-the-minute productions schedules, work instructions, tooling & maintenance information, all paperlessly. Another key element is that data is collected and available instantly. The business has complete visibility into labor and other costing information which comes directly from the machines via PLCs. For example, the machine stoppage show in the control panel, is now visible to the whole business and maintenance has been alerted. The control panel provides a “single source of truth”– captured at the manufacturing moment – to enable quicker responses, deliver confidence in the data, and enable faster decision-making. Let’s see how it works. An operator logs in by scanning a badge, key fob, or by typing their badge number. The workcenter can now record who’s doing the work for traceability and labor hour recording.

In this case, the maintenance technician logs in to clear the robot fault. Once back in production, the operators can go back to work. Just like any other web application, you can use the browser controls to go “back”. Here you can see that the status of the Welder has been changed back to green. With the Plex Control Panel, you can eliminate paper-based processes and you won’t have to sign into multiple systems. The Control Panel is a single, unified “mission control” that presents, collects and stores data in real time. Notice that all related production information is on the screen. Here, the Job field gives the operator everything they need to execute the scheduled job. Each box controls a separate aspect of production such as documentation, inspection or quality. It records production, scrap, scheduling, and maintenance... all in real time. There’s even an area for the front office to send communications directly out to all of the workcenters. And of course, it is completely customizable. Here the operator can check on the status and life of any required tooling for their job. Plex “operationalizes” quality with a completely integrated, data-driven system that records and monitors inspections using checksheets. But the most important purpose of the Control Panel is to produce something. Getting started is a simple matter of entering inventory. Notice that the panel shows red because no inventory is loaded yet, but as we load inventory, it turns green to show that it is available for production. Inventory can be loaded by simply scanning the container with a bar code scanner.

Once the welder has completed its cycle for the required number of units, production is recorded. Instantly, the Plex database e has accounted for the consumed inventory. Plex controls operational behavior with an intuitive control panel that connects your operator to your shop floor to reduce errors and streamline production. To learn more or see a more detailed demonstration, please contact Plex at 855-534-8012 or visit plex.com/contact.