Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Subscribe to Our Blog

For a monthly digest of expert insights, data points, and tips like the ones in this article.

The Last Mile in Your Quality Journey: Building a Quality Culture for Continuous Improvement (Part 3 of 3)

Guest Post

This is the third and final blog in a series focused on quality management. The first two blogs covered the importance of digitized quality processes and extending quality beyond a manufacturer's four walls. The third and final step I want to cover is the natural progression in Quality: the importance of building a quality culture or mindset across the enterprise.

Quality is an ongoing, evolving process within manufacturing, one where there is always progress to be made. An important objective for any successful quality management program, one that manufacturers are very familiar with, is to strive for continuous improvement.

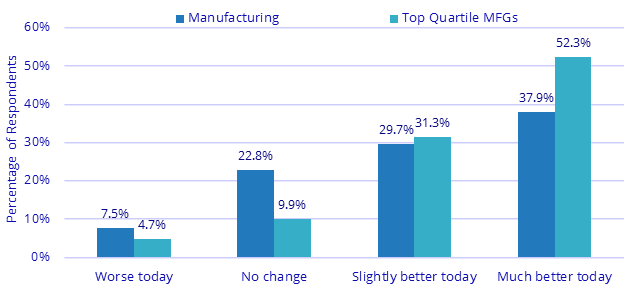

Historically, many manufacturers have approached quality in a siloed manner – letting quality groups handle any issues or non-conformances and not giving it much additional thought or exposure. However, this mindset is changing. To be successful, every employee must be bought in and dedicated to contributing to improving quality. In fact, successful manufacturers (top quartile of maturity) are the ones leading the charge when it comes to breaking down quality silos — and the results on performance stand out (Figure 1).

Figure 1: Product Quality Performance Over Past 2 Years

Source: IDC Future of Operations Survey – July 2021

A large contributor to data silos in manufacturing are manual or paper-based systems. If someone does not have access to relevant quality information, they may not even realize that issues are occurring. Simply providing employees access to this data, with the context of how this drives Company performance, can do wonders for building a quality culture, and digital quality tools and technology provides the foundation needed to have access to this data. OEE, first pass yield, cost of quality, on time and complete delivery, customer complaints, returns, etc., are all KPIs that should be available and monitored in real time and engrained in the continuous improvement process.

As employees identify issues, drive improvements, and are acknowledged for those improvements they will become even more invested over time. An additional benefit of this approach is that employees who have traditionally spent excessive amounts of time in paper chases can now focus their attention on more value-add activities, further supporting continuous improvement efforts and a quality culture.

These are all steps that successful manufacturers are more likely to take, which is why over half of the respondents of this group have seen large improvements in product quality over the past two years.

Additional capabilities that successful manufacturers are more likely to have in place include the following:

- Continuous improvement teams formed and focused on quality processes across operations and suppliers

- Operations and supplier audits performed regularly and benchmarked to improve quality performance over time

- Mock recalls performed regularly and benchmarked to improve quality performance over time

- Analytics used to provide predictive insights based on captured quality data

- Focus on quality throughout the customer lifecycle, including quotes, orders, product, issues, and responses

An important approach that successful manufacturers take is to build cross-functional teams aimed at making improvements across the enterprise. These teams can drive buy-in throughout the organization and help to change culture. In addition, while developing a comprehensive quality program can take a lot of effort, it is also important to continually monitor results to ensure that the program is performing adequately. Audits should be conducted to help further a culture of continuous improvement and provide visibility into historic and current quality performance. This also ensures that suppliers are following processes compliant with Standard Operating Procedures (SOP).

While no company likes to even consider the possibility of a recall, it is always good to be prepared. Conducting mock recalls reinforces the focus that every employee should have when it comes to product quality and traceability. By having this mindset in place, and with the right digital tools to support audits, a manufacturer will be faster and more effective in their response if a recall is necessary.

Every manufacturer's quality journey is in different stages, but no matter where you are, progress is always achievable. Every step of the way, from digitizing quality processes, to extending quality beyond the four walls, and finally ingraining a quality culture across the enterprise, value is generated. Continuous improvement is a mindset that the industry has embraced for decades with much success, leading manufacturers understand that this holds true for quality management as well.