Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Plex

Finite Scheduler

Your production schedule, smarter

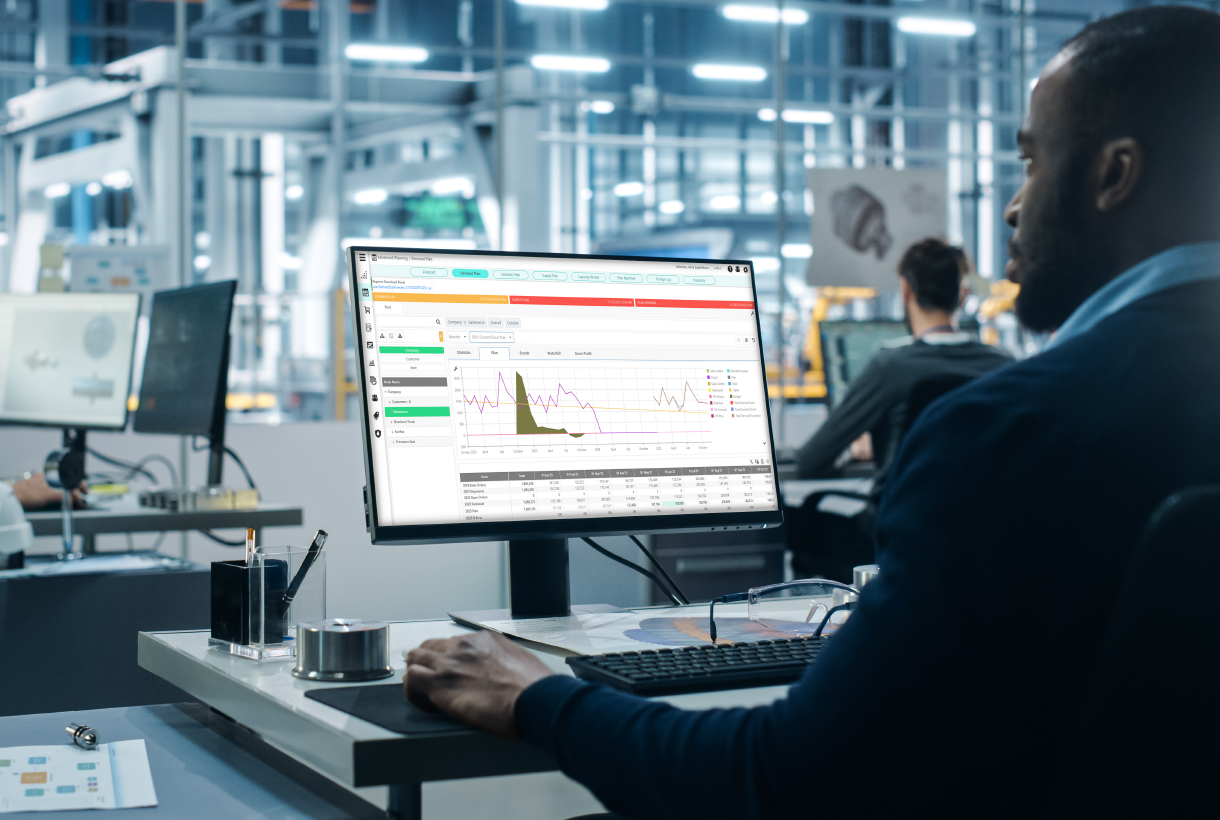

Production scheduling is the backbone of every manufacturing plant floor, serving as the connective tissue between organizational planning and execution. If there’s a gap in coverage, feel confident in the modern power of the production scheduling software behind Finite Scheduler. Finite Scheduler improves scheduling accuracy, increases throughput, and drives on-time delivery by utilizing manufacturing production data.

Create production flexibility

Review optimized production schedules and select the one that best fits your operational needs

Reduce on-hand inventory

With production scheduling that’s informed by available resources, on-hand inventory is reduced and efficiently put into the hands of customers.

Improve on-time delivery

Finite Scheduler smooths the production process with optimized scheduling, increasing accuracy and ensuring product makes it out the door.

Minimize changeover/setup times

Digitally model critical resource constraints and operational processes so that the production schedule makes the most of every minute in a day.

Reimagine your production scheduling

Scratch the guess work and use technology for a smooth path forward. Increase customer satisfaction while minimizing operation changeovers. Learn more about how Finite Scheduler will reimagine your production scheduling.

Production scheduling powered by pillars of smart manufacturing

Plex Finite Scheduler considers all factors influencing your production operations, ensuring the production schedule is highly optimized.

-

Connect

Connect organizational planning with manufacturing execution without any work arounds.

Image

-

Automate

Automate rapidly generated, data-informed production schedules

catered to your operational needs.Image

-

Track

Track additional influences, like workforce availability and equipment downtime, for flexible and accurate production scheduling.

Image

-

Analyze

Analyze modeled resources constraints and production processes to produce optimized production schedules.

Image

Plex Finite Scheduler Features

-

Resource constraint modeling

Create production schedules that reflect available production resources, like equipment, tooling, storage devices, pools of labor, and skilled/certified employees

Production process modeling

Model different steps of operations (setup, cycle, teardown/clean-down), capacity type, buffer type, and wait time constraints

Optimized scheduling generation

Speedily generate production schedules optimized for various business objectives

Interactive user interface

Easily review production schedules through a user-friendly interface