Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Challenge

Identify use cases and implement the latest in automation and digital transformation technology to improve OEE, empower workers and gain a competitive advantage in a highly regulated and competitive industry.

Solution

Guelph Manufacturing Plant

- Vuforia Augmented Reality software for industrial operation

- Harpak-ULMA machine-based AR experiences

London Poultry Processing Plant

- FactoryTalk® View SE, FactoryTalk® AssetCentre

- ControlLogix® 5580, CompactLogix® 5380

- PowerFlex® Variable Frequency Drives

- POINT I/O™ and POINT Guard I/O™ modules

- ThinManager®

- Emulate3D

Brampton Manufacturing Plant

- Plex Production Monitoring

- FactoryTalk® View SE, FactoryTalk® AssetCentre, FactoryTalk® Historian

- ThinManager®

- Kepware

Results

Guelph Manufacturing Plant

- Improved operator efficiency and training

- Improved OEE

London Poultry Processing Plant

- Enhanced product flow

- Reduced operating costs

- Achieved accuracy greater than 99%

Brampton Manufacturing Plant

- Achieved a better understanding of throughput

- Reduced downtime

Innovation and Digital Transformation in Response to Market Demands

Price pressure and competition for skilled workers is fierce in the protein industry. To be successful, food producers like Maple Leaf Foods must find better ways to capture more value from the equipment on their plant floors—and attract, train, and retain workers. Paired with the tight talent landscape, the global demand for food continues to grow, causing more challenges. Food manufacturers are under increased pressure to adopt automation and carbon neutral methods to improve operational efficiency, seamlessly integrate equipment, gain visibility across their systems, and secure IT and OT networks.

As the world's first carbon-neutral food company, Maple Leaf Foods has embraced automation and digital transformation at every level to drive efficiency and quality. The company has formed strategic partnerships and launched innovative programs at multiple facilities. These programs allow them to try new applications for automation and digital transformation technology – gaining a competitive edge by using the latest technologies to improve quality and productivity.

With a strong reputation for quality and innovation through brands like Maple Leaf, Schneiders, and Greenfield Natural Meat Co., the food producer continues to lead the industry by integrating cutting-edge technologies to enhance production and sustainability. Here, we’ll take a look at three of these projects.

Project #1: Boosting Training and Efficiency with Augmented Reality (AR)

Leadership at Maple Leaf Foods’ Guelph Manufacturing Plant identified a need to improve OEE and worker training. Maple Leaf Foods, along with Rockwell Automation and PartnerNetwork™ Partners Harpak-ULMA Packaging and PTC, set out to develop an AR- based training program using Vuforia® Expert Capture.

To begin, Harpak-ULMA deployed its embedded OEE Application, which automatically calculates, monitors, and reports packaging line performance in real time. Next, Harpak- ULMA deployed the entire library of PTC AR applications and created its own machine- based AR experiences.

Most AR user experiences leverage the machine’s digital twin, a dynamic model that virtually represents the physical machine. Digital twins enable life-like animation that allows workers to simulate a maintenance routine or operation before interacting with the machine. Digital twins also allow personnel to virtually see inside an operating machine to identify the location and condition of components without stopping production.

The pilot project quickly demonstrated the value of AR in a packaging line. For example, the OEE application delivers self-diagnosing machine reports that identify machine downtime and high-priority action items by shift. Using remote connectivity, the Harpak- ULMA team monitors these reports daily, identifies any high-frequency stoppages – and then builds step-by-step AR-based remediation routines that operators can access in real time.

AR-based training is underway and the company is in the process of evaluating the benefits of its implementation. They anticipate that the interactive, visually intensive training will help minimize language barriers, decrease worker error – and reduce training cycles in an environment that often experiences high staff turnover.

Project #2: Establishing a Power & Control Infrastructure for the Largest Poultry Processing Plant in the World

A core part of the Maple Leaf Foods’ strategy to build resiliency within their manufacturing facilities is to coordinate with strategic partners and suppliers to implement a standardized system for controlling, visualizing, and managing operations. This system is used across manufacturing facilities. The approach allows Maple Leaf Foods to dramatically reduce operator training, be nimbler with staffing, and be better positioned to respond quickly and effectively to events that happen at any facility.

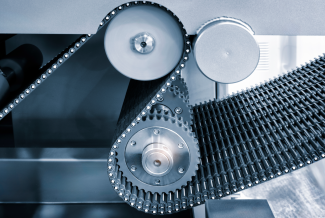

Due to its established relationship, Maple Leaf Foods entrusted RidgeTech Automation, a System Integrator in the Rockwell Automation PartnerNetwork to architect, manage, and implement this standard system. The two companies worked alongside Rockwell Automation to design a common controls architecture using ControlLogix® 5580, CompactLogix® 5380 alongside PowerFlex® 525 Variable Frequency Drives (VFDs), POINT I/O™ and POINT Guard I/O™ modules. A SCADA system for process control and monitoring was also built using FactoryTalk® View SE. This standard system is now used for any new build.

In 2021, Maple Leaf Foods began construction in London, Ontario to build the largest, most technically advanced poultry processing plant in the world. Inside the 660,000 square foot facility would be more than 4,000 pieces of equipment. The project was huge: 175 PLCs and over 1,500 VFDs were implemented.

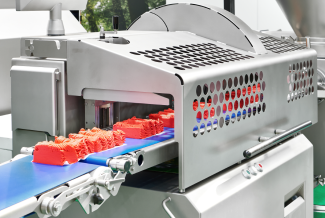

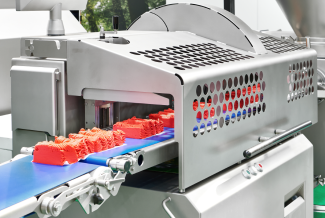

Once the build phase was complete, Maple Leaf Foods looked for ways to optimize production. One area of focus was the grading and packaging area of the plant. In this area, complex equipment sorts various cuts of poultry and then sends them through a tiered network of highway conveyors. To minimize product waste, Maple Leaf Foods wanted to achieve the highest level of sorting and conveying accuracy.

RidgeTech used Emulate3D™ digital twin software from Rockwell Automation to create a digital twin of the process. Then, they modeled traffic flow and identified bottlenecks and underutilized areas within the conveyance highway. Machine learning technology was applied to the simulation to find the optimal material flow. The entire study was completed digitally, while production continued. The result was a system design that achieved material handling accuracy of more than 99%.

Project #3: Creatively Leveraging Plex Production Monitoring for Further Standardization

The Maple Leaf Foods team identified an additional spot for standardization within their new system—they wanted to figure out how to best craft terms of performance agreements with the OEMs providing equipment to their manufacturing facilities. To achieve this, they selected Plex Production Monitoring (PM); however, the application of this Plex product would be outside of the typical application. Instead of using it to track OEE, Plex PM would be used to track OEM equipment performance.

To ensure a seamless and creative integration of Plex PM, Maple Leaf Foods once again partnered with RidgeTech. RidgeTech managed the hardware and OT layers and also coordinated with both the Plex team and equipment OEMs. To leverage Plex PM for OEM equipment performance data, they used Plex PM to gather metrics like OEM downtime codes, line statistics (if the line was starved upstream or downstream), alarms, and other critical machine insights. This information is then utilized to write the terms for OEM performance agreements. Maple Leaf Foods’ addition of Plex PM is part of an effort to create consistent downtime data across facility machines with zero operator intervention.

This project is currently on-going at Maple Leaf Foods’ Brampton manufacturing plant. Although not its intended application, Plex PM has already improved the company’s

overall equipment effectiveness (OEE) due to the full visibility into equipment performance and mitigated downtime. Should they continue witnessing positive results, the Plex smart manufacturing tool will be folded into Maple Leaf Foods’ standard technology suite and implemented into additional facilities accordingly.

Maple Leaf Foods Serves Up Sustainability through Innovation

Maple Leaf Foods' commitment to leveraging advanced automation and digital technologies has not only enhanced its production efficiency but also solidified its position as an industry leader in sustainable food processing. The company's collaboration with RidgeTech Automation, Rockwell Automation, Harpak-ULMA Packaging, and PTC has demonstrated the transformative power of technology in tackling industry challenges, from worker training to operational optimization. As they continue to innovate with cutting-edge solutions like augmented reality and digital twins, Maple Leaf Foods is paving the way for the future of food processing.