Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

One Line, Many Batteries: How Ionetic and Rockwell Automation are Making Electrification Easier

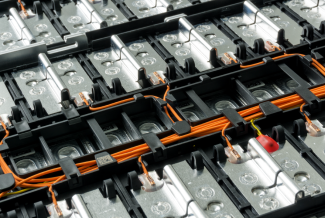

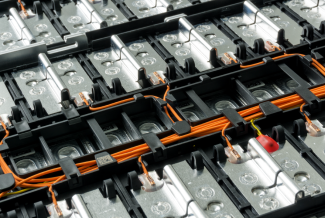

The world’s leading automotive OEMs produce millions of vehicles each year, leveraging Tier 1 suppliers’ capabilities to develop custom EV battery packs in-house and at scale, driving down unit costs. In contrast, thousands of niche manufacturers – those who produce fewer than 10,000 vehicles annually – face a different challenge. With lower sensitivity to unit costs but limited development budgets, many rely on off-the-shelf battery designs that don’t fully meet their packaging needs. Now, there is a third option.

Challenge

- Niche and low-volume OEMs, producing fewer than 10,000 vehicles per year, struggle to access battery packs tailored to their needs.

- Off-the-shelf battery packs often compromise on packaging, performance, or integration, limiting vehicle design flexibility.

- Custom battery packs from Tier 1 suppliers require high volumes and significant investment, making them inaccessible for smaller OEMs.

- Traditional battery manufacturing lines are costly, rigid, and slow to adapt, creating barriers for low-volume production.

Solution

- Ionetic partnered with Rockwell Automation to develop Arc Fab, a flexible manufacturing system capable of producing multiple custom battery pack designs on a single line.

- Emulate3D™ digital twin technology enabled virtual commissioning and process validation, reducing setup times and de-risking production.

- Plex Smart Manufacturing Platform automated production tracking, optimized workflows, and improved visibility across operations.

- iTRAK® Intelligent Track Systems introduced flexible motion control, allowing rapid reconfiguration for different pack designs.

- FactoryTalk® DataMosaix™ provided real-time data insights, including energy usage mapping, to optimize production efficiency and sustainability.

Results

- Setup time reduced by up to two-thirds through virtual commissioning and process simulation.

- Time to market accelerated by up to 25%, enabling faster delivery of custom battery packs to OEMs.

- Capital expenditure reduced by 5x per GWh, making manufacturing capabilities more accessible to low-volume manufacturers.

- Production flexibility unlocked, with the ability to manufacture different battery pack configurations on the same line.

- Energy efficiency improved, with data-driven insights identifying and eliminating production inefficiencies before manufacturing begins.

One Line, Many Batteries

Imagine a manufacturing line as versatile as a highly skilled tailor, able to create bespoke suits designed precisely to the needs of the customer. However, imagine the tailor could create a bespoke suit in a matter of hours, not days, and at a price comparable to that of a high-street retailer. While perhaps a somewhat extended metaphor, this is the essence of the partnership between Ionetic and Rockwell Automation. Together, the two companies successfully apply this philosophy to bring never-before-seen solutions to the world of electric vehicles and their batteries.

Challenge

Until now, niche and low-volume OEMs have had limited choice when it comes to EV battery solutions. Standardized off-the-shelf packs offer reliability but can lack the flexibility needed for unique vehicle designs. On the other hand, fully bespoke battery programs from Tier 1 engineering service providers require significant volumes and investment, putting their benefits beyond the reach for many innovative OEMs. This means that smaller manufacturers have experienced a slower path to electrification while larger OEMs have moved the needle with custom solutions tailored to their scale.

By leveraging Rockwell’s cutting-edge digital twin technology and Ionetic’s AI-supported, software-accelerated systems, we are finally breaking this cycle, delivering industry- transformative custom battery packs that meet the performance, cost, and time-to-market needs of a wide range of modern OEMs.

Why the partnership exists: solving systemic challenges

There is no doubt that electrification is the future. Despite the widely reported slowdown in electric vehicles sales in Europe, the long-term trend is for sustainable growth. Yet despite the growth in gigafactories, the cost of battery packs continues to be a challenge, accounting for as much as 40% of an EV’s total cost.

For high-volume vehicle platforms, producing hundreds of thousands or even millions of units, this cost ratio can be absorbed over time. But the barrier to entry for smaller and niche manufacturers is considerably more significant – sometimes impossible.

While electrification is key to achieving net-zero emissions, many smaller OEMs struggle to access the right battery solutions. Because traditional manufacturing methods are designed for high-volume production, it’s harder for niche manufacturers to find battery packs that fit their specific needs. Addressing this gap requires a flexible and efficient approach that enables innovation without the barriers of conventional development models.

Systemic challenges:

- Rigid manufacturing models

Traditional manufacturing lines are time-consuming to build and expensive, ill-suited to the agility needed by low-volume OEMs. They require significant up-front investment (sometimes into the tens of millions) and are built to service a single battery pack design, leaving the OEM unable to adapt designs as battery technology evolves or vehicle designs change.

Compromised performance

Off-the-shelf packs often fail to meet critical performance or packaging requirements, leading to inefficiencies in weight, size, and energy. They also inhibit the ambition of any manufacturer wishing to create a truly unique vehicle design. So much of vehicle design and performance is integral to, and literally built around, the battery.Adapting a vehicle design to work with a ‘standard’ battery does little to enhance a vehicle’s aesthetic appeal or the packaging of its various chassis systems and can result in a sea of sameness with identikit designs – leading some to go so far as labelling EVs as mere appliances. The only way to ensure a brand’s DNA is built and maintained in the transition to EVs is to design vehicles and batteries in unison.

- Prohibitive costs and timelines

Bespoke battery pack development with Tier 1 suppliers can take more than four years and cost upwards of $30 million, an insurmountable barrier for most niche OEMs. Even if budget is available, delays to the project for any number of reasons, be they internal or market-driven, quickly begins to erode already slim profit margins – a problem that can only worsen given the rapid rate of improvement in battery cell performance, year-on-year.

Solution

Smarter, faster, more scalable

Designing custom EV battery packs is just one piece of the puzzle. Manufacturing them at scale, affordably and efficiently, has long been the real challenge. With traditional development processes not suited to keeping pace with demand, a completely new approach is needed for niche and low-volume EV manufacturers for applications from supercars to buses, trucks, or even boats. It’s a problem that Ionetic has spent the last three years trying to solve, and by taking a completely new approach in partnership with Rockwell, it is confident it has made the breakthrough. Ionetic and Rockwell Automation have partnered to combine their strengths in software, hardware, and flexible fabrication technologies with advanced automation. Ionetic’s Arc platform integrates AI-driven design, rapid virtual validation, and software-enabled optimization, slashing development time and cost. But without flexible production, even the best designs can stall. That’s where Arc Fab, its adaptable manufacturing system, comes in.

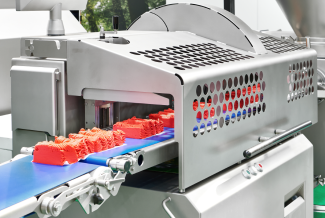

Powered by Rockwell’s automation and digital twin technology, Arc Fab enables multiple custom battery packs to be built on a single line, reducing commissioning time by up to two thirds, significantly reducing time to market for OEMs. With smart factory technologies like Emulate3D™ dynamic digital twin software, Plex Smart Manufacturing Platform and independent cart track technology, it is creating a new standard for battery pack manufacturing: one that’s fast, cost-effective, and scalable for niche and low-volume OEMs.

Results

- Flexibility at scale

By integrating Rockwell's iTRAK® Intelligent Track Systems, a single manufacturing line achieves enhanced flexibility, enabling the production of multiple battery pack designs for multiple customers. This advanced motion control technology allows for rapid changeovers and efficient handling of various configurations, tailored to individual OEM needs.

- Shorter timelines, lower costs

Faster commissioning, reduced development costs, and an optimized manufacturing process deliver competitive advantages for OEMs.

Progress made and proof of innovation

The partnership is already delivering industry-leading results, transforming battery pack manufacturing in three critical areas: flexibility, efficiency and operations.

- Flexibility with Emulate3D™ technology

Rockwell’s Emulate3D™ dynamic digital twin software enables Ionetic to simulate and optimize production lines virtually, creating bespoke battery packs without costly new tooling investments. This enables the crucial customization at scale needed by its customers to stay competitive when time-to-market is more critical than ever. Going one step further than a standalone digital twin, Emulate3D software uses the same code as the physical manufacturing line, ensuring that processes validated in the virtual world work consistently in reality. This enables seamless validation prior to commencing manufacturing.

Cost and time efficiency

Virtual commissioning in Arc Fab, powered by Rockwell Automation’s Emulate 3D digital twin software, reduces the time required to set up manufacturing lines up to two thirds, leading to faster commissioning for new designs. By integrating the Plex Smart Manufacturing Platform, it further streamlines operations by automating production tracking, optimizing workflows, and ensuring real-time visibility into manufacturing performance. This means that its OEM customers can bring vehicles to market significantly quicker, enabling OEMs to innovate rapidly and meet the growing demand for EVs.The efficiencies unlocked through automation and digital validation, thanks to Ionetic’s partnership with Rockwell Automation, reduces the overall capital expenditure (CapEx) needed to establish manufacturing capabilities – five times lower CapEx per GWh – making it accessible for smaller OEMs.

- Operational excellence and energy usage

Simulations in Emulate3D dynamic digital twin software identify bottlenecks and optimize workflows on-demand, ensuring higher throughput and increased productivity. Industrial data ops solutions, such as FactoryTalk® DataMosaix™ from Rockwell Automation, with applications like the Energy Manager, map energy usage along the production line, allowing inefficiencies to be addressed before production begins, supporting sustainable manufacturing practices, reduces operating costs and enhances overall energy efficiency in battery pack production.

“Battery manufacturing is typically slow and expensive. By combining Rockwell’s automation and digital twin technology with the efficiencies of Arc, we’ve significantly cut the time and cost of setting up production lines,” said James Eaton, CEO and founder, Ionetic. “This means we can commission customer lines faster, reduce delays, and make scaling up far more predictable. For smaller OEMs, that makes custom battery pack production more accessible and flexible. With a choice of different cell formats, chemistries, and system voltages, our customers can quickly optimize their electrification strategy with battery packs tailored to their needs.”

“Digital twins are, of course, widely used to simulate manufacturing processes in a broad range of industries,” explained Åsa Arvidsson, regional vice president central, east & north region, Rockwell Automation, “but while all are digital representations of physical entities being assessed in a virtual world, not all are equal. Many are, in effect, more akin to a video game, simply creating lookalike 3D models to create the appearance of a simulated factory. But with Emulate3D, we’re creating a genuine digital twin of the facility, controlling the robots in the virtual facility with the actual code we’ve written for the real thing. This gives us complete confidence that when the facility is installed, we know exactly how they’re going to perform.”

The road ahead: scaling innovation

The EV industry has long been constrained by rigid battery manufacturing models that stifle innovation. But it no longer has to be that way. This partnership between Ionetic and Rockwell Automation turns this on its head. By combining Ionetic’s expertise in battery technology with Rockwell’s industry-leading digital tools, they are proving that custom battery packs can be both fast-to-market and affordable, unlocking new opportunities for OEMs and investors alike.

The Ionetic-Rockwell partnership is just beginning to unlock the full potential of digital manufacturing in the EV battery space.

For niche and low-volume OEMs, the road to electrification is no longer a compromise, it’s a potential competitive advantage. This collaboration lays a strong foundation for Ionetic's future growth, offering reduced risk, faster timelines, and scalable solutions. Together, Ionetic and Rockwell are building the future of battery manufacturing, one bespoke pack at a time.

About Ionetic

Ionetic is a software-accelerated, end-to-end battery pack developer dedicated to revolutionising the way battery packs are brought to market.