Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Subscribe to Our Blog

For a monthly digest of expert insights, data points, and tips like the ones in this article.

If you’ve ever wished for a magic pill that could boost the bottom line while making you look like a superstar employee, then smart manufacturing is the prescription of your dreams.

There’s a revolution happening right now in this industry as the adoption of technology skyrockets. If the tech conversation isn’t already happening in your company, then you’re the one destined to bring hard facts to your manager’s table while putting you one step closer to having a seat at that table. This is how your old classmate on LinkedIn got that promotion – they ushered in real change, putting their company on the cutting edge.

It’s time for you to be that same spark with these key stats from the 6th Annual State of Smart Manufacturing Report. After all, your career progression is directly tied to how much impact you make on your company. If you don’t show these insights to your boss, someone else will.

Most organizations like yours already believe in smart manufacturing – relying on technology for connecting, automating, tracking, and analyzing value chains to streamline processes and generate actionable, real-time data. If your company is part of the 20% that isn’t planning for this smarter future, then you’ve got a clear opportunity to introduce the concept. Even if your leadership already knows smart manufacturing is important, are they actually doing anything about it? Either way, you have a chance to become your company’s smart manufacturing champion.

The cloud is another huge priority for most manufacturers. Where does your company stand? On top of that, 41% of companies are increasing spend on cloud technology. That means even if you’re already using the cloud, there’s still room to grow within it and leverage its capabilities even more. This is no time to sit back. Make sure your boss knows that there’s still room to grow here.

If your boss ever asks you why there’s so much buzz around smart manufacturing, this is your answer. Your competitors are breaking down silos across their entire organization, from the shop floor to the top floor. In fact, 70% of manufacturers are already using software or hardware to connect these important elements of their business. When your people, technology, and processes are completely connected, that’s when you can reap the benefits you see touted in trending headlines.

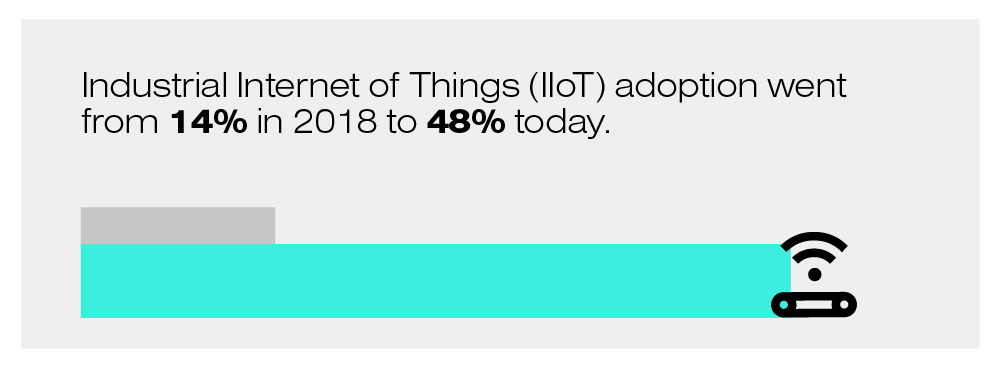

Have you ever felt the window of opportunity tangibly start closing on something? This stat should produce that exact feeling. Adoption of IIoT, that which makes smart manufacturing possible and allows machinery to communicate actionable data, is skyrocketing. As of this writing, just under 50% of manufacturers are relying on it. That means the tide is about to turn. Failure to act now means you’ll fall behind a soon-to-be majority of smarter manufacturers. Even if your company can’t act on IIoT fast enough, showing this stat to your boss today will allow you to say “I told you so” tomorrow.

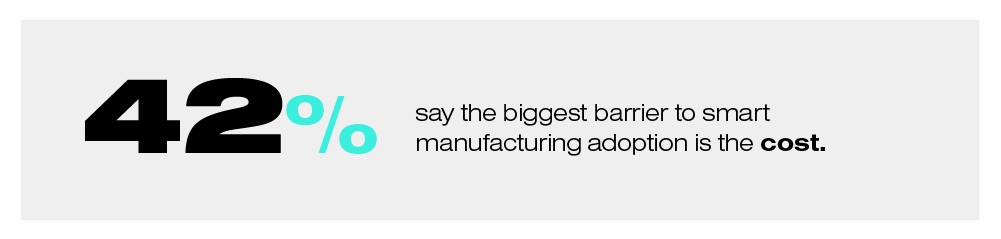

When you bring up smart manufacturing to your boss, do they pump the brakes and mention the price tag? This fear of cost stems from two misunderstandings. One is a pure assumption: if a piece of tech is so great that it can revolutionize operations, it must cost a fortune, right? The other is not comprehending the massive ROI on the table. Anyone can talk themselves out of a purchase based on initial cost. But look at the savings and additional revenue smart manufacturing brings, and it becomes a financial no-brainer. Make sure your boss sees their fears are unfounded.

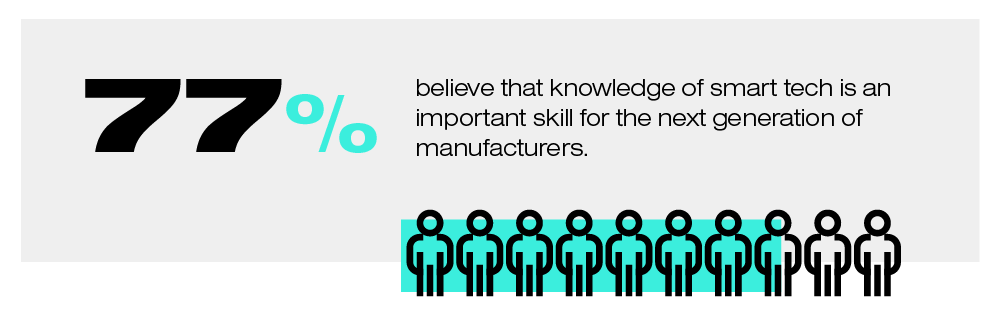

When your boss gets promoted, who will they recommend for their role? If they’re like most in their position, they’ll be looking for someone to take initiative when it comes to smart technology. If they’re not following in the footsteps of their respected peers, this stat might open their eyes to the leaders of the next generation (that means you). There’s no denying that the future is digital. Show your boss you’re in the know and part of that growing smart manufacturing wave.

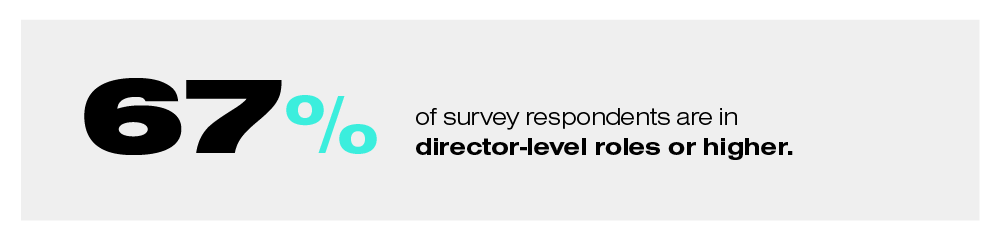

The above stats (plus any you might discover in our full State of Smart Manufacturing Report) were mostly generated by leaders in roles you aspire to reach. You’re looking at exactly what industry executives, VPs, and department heads think about smart manufacturing. These are the insights they care about. Make yourself look good – and your boss look even better – as you usher in positive change and become the face of the new generation of smart manufacturers.