Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

At A Glance

Although DECC was acknowledged by its customers as an industry leader for its innovative solutions, it had only kept up with evolving enterprise resource planning (ERP) technology on an as-needed basis.

DECC was also challenged to maintain upgrades for its existing maintenance tracking system and gage tracking software that stored data on gages and calibrations. In addition to having multiple systems tracking different parts of the production process, the various applications did not communicate with each other. Receiving a comprehensive overview of the processes was challenging and time-consuming.

What DECC lacked was the ability to easily get a real-time view into the status of all processes within the plant and to share necessary information with its employees and suppliers.

The ERP Solution was Introduced by Another Manufacturer

DECC knew there were better options and that it was time its ERP solution mirrored the quality of its products. The company sought the best available solutions and did a great deal of due diligence to determine which solution best met its needs. DECC became aware of the capability of Plex Manufacturing Cloud ERP while attending a presentation by automotive parts manufacturer GR Spring & Stamping.

DECC was impressed by Plex’s focus on capturing information on the shop floor and making it visible throughout the organization. In addition, Plex had all of the functional capabilities DECC was seeking without the high cost of configuring a custom solution. DECC also appreciated the pricing model, which includes a single cost for the entire company, regardless of the number of users; pricing isn’t determined by the number of seats that have access to the data.

Consolidation and Increased Visibility, the Desired Results

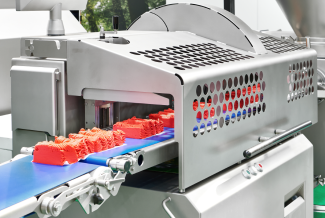

The results have been immediate and impressive. DECC now is essentially a paperless facility and is functioning with enhanced traceability, streamlined workcenter operations, electronic job processing, checksheets, checks and balances added to bills of material (BOMs), and employee tracking. DECC uses a simplified production screen to track two data streams: one for parts and the other for coatings.

Prior to deploying Plex, DECC didn’t have a dedicated costing system. When a report was deemed necessary because of a perceived problem, the engineering department would manually gather the required information to determine if remedial steps were required to improve the process.

Now DECC is able to continually track and control costing as a routine part of the process, not just as a reactive measure when management raises a concern. This allows the company to anticipate problems before they occur and quickly take the action necessary to mitigate problems. Costing is now associated with employee IDs so management knows who is participating in each step of the process.

Plex provides access to data that wasn’t available before, data that helps the company make informed decisions that contribute to the bottom line. DECC did not have lot traceability prior to deploying Plex; it couldn’t track scrap or rework rates. There was limited employee interaction with the old system and when employees did capture information, they didn’t have confidence in its integrity.

Traceability is Key to Improved Process

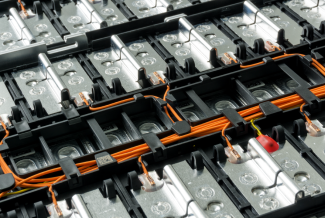

DECC has seen major benefits in the manufacturing process due to Plex’s traceability function. Parts now move from process to process with a serialized job number on a barcode label. These unique numbers are tracked by Plex and interface with the control panel. DECC can see the date, time and duration that a specific part has been at each step. This allows quality managers to easily detect if there are any issues or deviations in the process. When problems occur, they can be investigated quickly and easily because each part leaves a detailed history, allowing solutions to be quickly introduced.

The advantages of traceability with Plex Cloud ERP are not limited to customer parts but also are used to identify and track coatings, solvents, and blends. DECC’s process involves applying either raw coating or mixing raw coatings with solvents to create blends specific to customer needs. Plex tracks the quantity of coating and solvent in each blend; the amount of coating or blend used at each operation; and the location of every coating, solvent, and blend container throughout the plant. This is possible due to a barcode label with a serialized number attached to every container.

For example, when an operator uses coating from a container, the person, time, and quantity are logged in Plex and a history of that specific container is developed. All container histories link to form a traceability tree, which graphically displays all the containers associated with the original container. It acts like a “family tree” for coatings and solvents. The “mother” raw coating container and “father” solvent container are at the top, with “children” blend containers branching out. Traceability for coatings, solvents, and blends is a notable improvement for DECC, and will only improve as more histories are captured.

Inventory Accuracy Brings Peace of Mind

DECC’s introduction of a barcode inventory system has lowered storage requirements, increased count accuracy, and improved overall efficiency. DECC’s inventory system is updated to support the technology of wireless barcode scanners and mobile computers. The 100,000-square-foot facility is now equipped with full wireless access, which allows for full mobility. When supply items are received, a label is automatically printed to tell the inventory manager what the item is and its exact shelf location. The item is added to the inventory database, which includes descriptions and photos of each item. This allows DECC to always have an exact, real-time inventory. The accurate inventory system has lowered DECC’s storage requirements by 30 percent.

Information Sharing is the New Approach

Plex Cloud ERP offers manufacturers the opportunity to give suppliers and customers visibility of its plans through its Control Plan feature. DECC is able to limit access to whatever information is relevant for suppliers, and helps suppliers efficiently provide products in the supply chain. Shop floor employees are now able to access data, and they appreciate how the system helps them drive improvements, reduce waste, and operate more efficiently. They now are actively contributing to the company’s strategy with their valuable shop floor perspective.

Enhanced Data Collection Improves Product Tracking

As a coating applications company, DECC is required to track data to adhere to environmental regulations. Prior to deploying Plex, the company was manually tracking data. The system was labor-intensive and prone to introducing bad data.

Plex allows DECC to record coatings as parts. Quantities are linked to usage and auto-depleted so the information is always accurate and automatically stored by the system. Now staff at DECC can easily track how much coating is used by each piece of equipment.

Unanticipated Benefits

Previously, DECC’s human resources staff had to enter data manually, often entering the same data multiple times. Plex’s HR function allows the information to be entered once to populate multiple locations.

Many of the shop floor employees had little knowledge of computers before the introduction of Plex Cloud ERP. They quickly picked up the skills needed to enter and access data, which resulted in an engaged workforce that now contributes more to the efficient operation of the company.

Takeaways

The deployment of Plex Cloud ERP at the DECC Company has resulted in improved manufacturing processes, a more engaged workforce, and better informed suppliers and customers. Data can be accessed at any time, from any location, through Internet access. Because Plex uses the cloud ERP delivery method, DECC has eliminated the need for servers to host the on-premise ERP application, daily backups, annual shutdowns for software updates, and the burden of expensive licensing fees.

The quality of the information at DECC now equals the quality of its products, enabling DECC to successfully compete in the global manufacturing arena

About The DECC Company

The DECC Company, Inc., is a family-owned business based in Grand Rapids, Michigan. The company is dedicated to solving customer problems through specialized coating applications and custom coating services. Initially founded to serve the unique needs of the automotive industry, DECC has diversified to provide coating services for a variety of industries: aerospace/avionics, food production, furniture, medical, and diesel industries and the military.

Industry: Industrial Manufacturing

Location: Grand Rapids, MI