Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

NHK Spring Reduces Costly Errors, Saves Time with Automated Reporting with Plex

IGear, Inc., is a technology company focused on improving manufacturing competitiveness by leveraging connectivity between people and technologies. The company was engaged by NHK Spring to design a solution that would ensure an error-free shipping protocol.

At A Glance

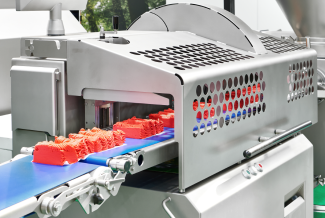

The packing and shipping of the springs require flawless precision as the shipping containers are brought directly to the shop floor at the OEM, where they are unloaded during the manufacturing process by robot assemblers. Human error could place the wrong spring in the cases, or improperly space the components, which would interfere with the robots’ ability to pull the springs consistently from the shipping container. A simple shipping error had the potential to cost the company tens of thousands of dollars to correct and could negatively impact its relationship with an important customer.

Temporary, but Costly, Solution

NHK Spring sought to ensure there were no errors in the process by hiring outside quality inspectors and dedicating internal personnel to double- and triple-check cases before shipment — an expensive solution that still didn’t guarantee a flawless packing process.

The company produces four variations of the springs for the various vehicles manufactured by the OEM, each identified by a specific color. In addition to ensuring the proper springs are loaded into each container, it is also critical to properly pack and space each component. Only with the proper spring accurately packed can the robots successfully grasp and insert the springs. An error in spacing or an improper spring could bring production to a costly halt, damaging the supplier’s reputation and negatively impacting the efficiency of the customer’s manufacturing process.

Technology Solution

NHK Spring was justifiably confident of the quality of its product but knew that the packing and shipping of the product must be improved to best serve the customer. It sought an effective and permanent solution from IGear, a company which specializes in enabling manufacturing excellence by connecting disparate technologies to enable superior product quality, greater productivity, and precise, real-time plant intelligence.

IGear fabricated a vision system that integrated with Plex to ensure consistently proper spacing and spring type. Its error-proofing protocol prevents the shipping of mixed parts or misaligned products — errors that could result in interrupting the manufacturing process at the end customer’s facility and require expensive corrective actions.

“Transactions validate machine set-ups, report production, and clear trays for shipment.”

At NHK, after a tray is loaded with springs, it is placed in a vision system fixture that locks the tray in place. The vision system developed by IGear takes an image and inspects the tray for errors. The vision system also checks for proper paint color, spacing and number of springs in each container. If there is a smudged or misaligned tray label, or if any error is detected, the operator is informed immediately via a human-machine interface (HMI) touch screen on the fixture.

Before the tray can be physically unlocked and removed from the vision system, the IGear system must complete a remote transaction with Plex. This transaction includes three steps: validating that the machine is set up properly, reporting the production of the tray, then clearing the tray for shipment to the end customer.

Quality Controls

The communication between Plex and the IGear system at NHK is done via a Web service call. If the transaction is completed successfully, the tray is released and the next tray is inspected.

If the Web service transaction fails for any reason, a message such as “unauthorized operator logged into machine,” is displayed on the HMI touch screen and the operator corrects the problem and initiates a re-inspection. Only a supervisor can manually release the tray with a password entered via the HMI.

The Web service transaction between Plex and IGear averages less than two seconds for the data’s round trip from NHK Spring to the data center at Plex Systems and back again. This response rate illustrates the effectiveness of leveraging Web services in time-critical functions. Using this validation process, NHK Spring has eliminated the need for additional quality inspectors and ensured a consistently acceptable product for its customers.

Results Meet Customer Needs

An added benefit of the vision system is the ability to store images of product shipments to refute claims, should they occur.

“The vision system for ensuring the packaging of spring shipments prior to shipping to the customer is a useful quality control feature and important to the entire manufacturing process,” says Hideki Katsu, vice president of NHK Spring Precision of America, Inc. “We ship our products with great confidence, knowing the quality of the shipping is as error-free as the springs themselves.”

Through the elimination of costly human errors during the packing and product labeling process, along with the time savings generated by the automated reporting functionality of the Plex system, NHK Spring Precision and IGear together have crafted a solution that is consistently successful in meeting the strict manufacturing requirements of its North American automotive OEM.

About NHK Spring Precision of America

NHK Spring Precision of America, a division of the Japan-based NHK Spring Company, Inc., produces springs for an automotive OEM’s supply chain in North America. The company uses Plex software to ensure its springs meet strict production quality requirements. However, NHK Spring was seeking to ensure there were no errors in the loading of the springs for shipping to the manufacturer, which could result in expensive fixes.

Industry: Automotive

Location: Louisville, KY