Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Lacking a single system that included MRP, PLC integration, and shipping and receiving, Ralco Industries found that inventory accuracy was a major issue. This inaccuracy led to overstock to ensure there was enough material on hand for jobs. Setups were not consistent, resulting in excessive overtime and expedited shipments. These issues led Ralco Industries to Plex.

At A Glance

We get more advantage from Plex than we could with SAP or a similar system. This is the system of the future. Any company looking to outperform its competition and invest for the future will find its way to Plex.

Ralco Industries was looking for a system that could improve processes, efficiency, and insight. Operations began to suffer from inaccurate data and a lack of visibility.

“In past years, our inventory accuracy was only about 50 percent,” says Jim Piper, President of Auburn Hills, Michigan-based Ralco Industries. “We conducted grueling physical inventories every month, and they would be off within the following week. We never knew if we had enough parts to build a setup.”

“Every time we did a setup, it was different. Each of our guys had his own method. This resulted in lost time, inconsistent product quality, scrap, expedited shipments, etc. We knew we had to fix our system.” Says Piper, “The lack of accurate data from our systems was causing a number of expensive issues—quality problems, scrap, overtime, expedited shipments, etc. We had to get our systems to work for us.”

Seeking One Solution

Given these and other challenges, Ralco’s goal was to find one system that could integrate all facets of its manufacturing business.

Ralco wanted to move away from separate manufacturing resource planning (MRP) incapable of machine PLC integration. Ralco also wanted to avoid stand-alone software for shipping and receiving.

After a detailed search, the company found that the Plex Manufacturing Cloud offered the most advantages over other solutions. The industryleading manufacturing cloud solution is fully integrated with the PLCs for all shop floor and engineering equipment.

The company noted that Plex could adapt to its unique business strategy and be customized to Ralco requirements. Says Piper, “Every other software company required us to adapt to their software.”

An Improved Process

“After switching to Plex, we now cycle inventories. Because of our improved accuracy in inventory, we can do setups faster, and we have been able to reduce our inventory on hand by 15 percent. Plex also has a ‘recipe’ system for setups, so each setup is exactly the same.

“There is no room for operator variation. If someone attempts to change the recipe, Plex communicates with the PLC and the press stops.”

Ease of Use

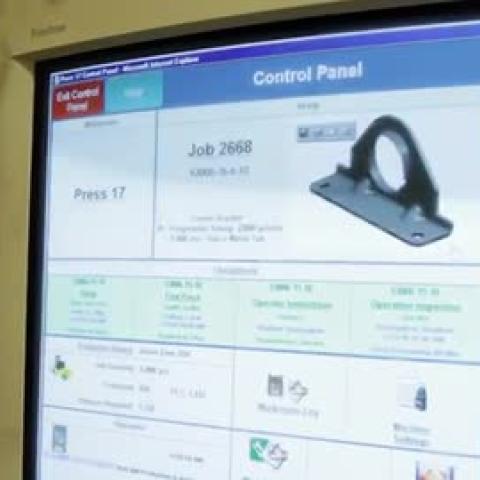

The Plex Manufacturing Cloud uses a simple, web-based interface and places few requirements on the operator.

Unlike software from other companies, Plex is accessed through a web browser. This allowed Ralco to avoid the cost and hassle of buying, installing, and maintaining the software and server.

Plex also supports and enhances the system, including all software upgrades, data backup, and professional system management, at its headquarters in Troy, Michigan.

Safe and Secure

According to Ralco, it was a relief to offload the major database and back-up responsibilities, although security was a big issue. In fact, the company reports that a staff member in the IT Department used to work for the CIA. He spent a month trying to break into the Plex system. He never could do it.

Says a Ralco representative, “Plex is an IT department on call, and because they maintain and upgrade everything for us, I’m now a one-man IT department. I handle network issues, PC software, etc., but Plex handles everything with their system. They are responsive and fast, and they care about the customer. Most issues can be addressed with a simple email.”

Fast Implementation

Ralco started its implementation with the Plex Purchasing function. Plex is designed so that you can add one function at a time or simultaneously install several. Ralco can now easily match receipts to internal purchase orders, and match purchase orders to invoices. The company has more control and security over purchase orders, and has actually reduced the number of purchase orders.

The improved efficiency saves about $100 per purchase order processed. After Ralco’s old MRP system crashed, the company took the plunge and subscribed to Plex functions including: Sales/ Customer Relationship Management, Materials, Inventory, Production Tracking, Scheduling, Shipping, Quality, Management, Communication, EDI, System Administration, and Security functions.

“Our Plex rep, Mig O’Brien, developed a plan on how to design, develop, and implement these functions, and they followed it,” says Piper.

“One thing we had learned from previous software companies is that you have to have an internal project manager and a dedicated person from the software company. They work with each other as backups, and it’s the only way to ensure the coordination required.”

Real Benefits, Real ROI

The Plex Manufacturing Cloud is so easy to use that Ralco was able to reduce training hours by more than 50 percent.

“Plex has the same Control Panel for every work area, which simplifies training,” says Piper. “Before, 90 percent of our training time was spent on computer training. But Plex is easy for employees to pick up. Now each employee can run every type of equipment. That’s huge.”

Results were huge too. Products are now of a consistent high quality. Premium freight costs were reduced by more than 20 percent per year. Now it’s a rare event to have to expedite a shipment.

Scrap rates are down by more than 60 percent. Downtime and employee turnover have both been reduced drastically. Inventory is down. Setup times have been reduced. And the paperwork and order tracking are now easy. “We were looking for a two-year payback, but it only took just over a year,” says Piper.

About Ralco Industries

Ralco Industries, Inc., is an ISO/TS 16949-certified tier-one and -two automotive supplier specializing in precision welded assemblies, metal stamping, design, tooling, and prototyping. The company serves worldwide OEMs with exhaust, steering, chassis, suspension, seating, and HVAC parts and assemblies.

Location: Auburn Hill, MI

Founded: 1970