Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Ultra Tool & Manufacturing Saves Thousands of Dollars and Hundreds of Labor Hours Annually with Plex

With a humble beginning in 1969 as a Milwaukee-based tool and die shop, Ultra Tool & Manufacturing has grown to include additional services like metal stamping, die design, and metal fabrication. Their world-class operation is headquartered out of Germantown, WI. While they might be located in a smaller town, Ultra manages a larger-scale operation. They have provided their customers with excellent quality and service for over 50 years and continue to thrive today.

This eagerness for growth is why Ultra has gone on to receive national recognition—the company’s leaders have never been afraid of embracing new technology. A new facility in 2015 opened the doors for larger presses and expanded capabilities, including the implementation of Plex’s Enterprise Resource Planning (ERP) cloud-based solution. Over the years, Plex ERP, which includes its Manufacturing Execution System (MES) solution, has helped Ultra improve quality, processes, and responsiveness. Since this implementation, Ultra identified a new need for their growing business: the ability to better control plant floor performance.

At A Glance

"One of my sole focuses right away was just figuring out what we’re really saving from a standpoint of automating production recording and label making. So in just those two things alone, we captured right around $48,000 of annual savings which basically paid for the Plex MES A&O product easily.”

Making Up for Lost Time

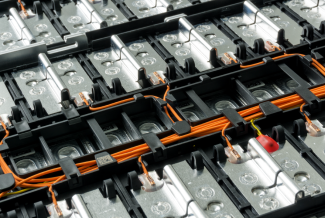

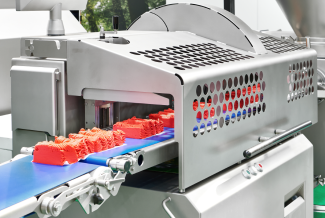

The need for improved plant floor performance introduced Ultra to Plex’s MES Automation and Orchestration (MES A&O) solution, which connects Plex MES to the plant edge to control information flow and processes adding efficiency, saving cost, and eliminating manual errors. When a company makes millions of parts per year, the ability to track and gain visibility is an important capability. Ultra recognized that lack of automation and insight into data at a granular level left a lot of room for mystery—and with mystery comes cost. For Ultra, that cost equated to tens of thousands of dollars in manual labor for setup and more than 240 extra operating hours each year.

When searching for their plant floor automation solution, Ultra identified a variety of pain points they hoped to be addressed. Overall, they lacked visibility on the plant floor. Little to no plant floor insight brought with it a domino effect of other issues: Ultra had no way of knowing machine rates, what they should be, or why an operator failed to meet rate expectations. Some issues, like an operator forgetting to log in or out of production, boiled down to manual error.

Plex MES A&O, a powerful low-code toolset that connects Plex MES to the plant edge, allowing for automation of tasks and orchestration of workflows to remove human error and manual oversight, offered Ultra the solutions they were looking for. Since implementing Plex MES A&O in June 2021, Ultra has experienced a variety of positive changes like increasing visibility into production and tracking data.

After starting with just one stamping press, Ultra moved through nine more over the course of a year and upgraded the controls on machines that were old or obsolete. Their implementation went beyond just machines and included training or retraining operators to utilize Plex MES A&O best. This was a crucial move for Ultra as their operators often hop from machine to machine. A big transition for Ultra, the implementation went smoothly as they broke up the process into sizable pieces

About Ultra Tool & Manufacturing

Ultra Tool & Manufacturing, located in Wisconsin, is a privately owned manufacturer focused on quality and repeatability for metal parts and tooling dies from design to production. Specializing in stamping and fabrication, Ultra Tool & Manufacturing produces precision metal components that serve the recreational vehicle, automotive, electrical, lawn and garden, small engine, and military defense industries. With just over 100 employees on board, 2023 marks 54 years of business for Ultra.

Industry: Industrial Manufacturing

Location: Germantown, Wisconsin