Now Available!

Get your copy of the 7th Annual State of Smart Manufacturing and hear from 300+ manufacturers in this new survey report!

Subscribe to Our Blog

For a monthly digest of expert insights, data points, and tips like the ones in this article.

Smart manufacturing enables manufacturers like you to adapt to a changing market and unlock long-term opportunities by connecting and automating their business. But where do you start?

With increasingly modular smart manufacturing technology options available, investment and implementation can be simple, seamless, and cost-effective. These incremental investments unlock value quickly and can be used to fund subsequent projects, acting as building blocks for smaller manufacturers or those without large capital investment plans.

Additionally, newer cloud options have opened up opportunities for manufacturers to take advantage of pre-built, turn-key solutions that don’t require a high level of knowledge or time investment from their limited resources.

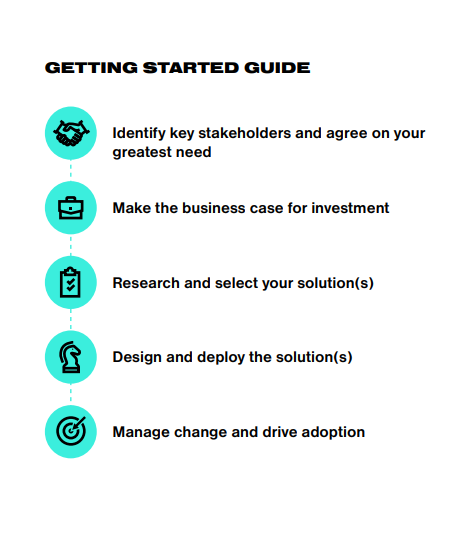

Below is a five-step plan to help your business — and your people — regardless of where you are in the technology adoption process.

Step 1: Identify Key Stakeholders and Agree on Your Greatest Need

Gather the people connected to this change – both decision makers and system users. Diverse perspectives clarify the problems that need solving, whether you’re dealing with disconnected systems, people, processes, and supply chains or unexpected downtime, poor quality, and lack of visibility.

- Where are your information gaps?

- Have you assembled the key stakeholders?

- What are the operational challenges you’re trying to solve?

Step 2: Make the Business Case for Investment

Develop your business case by highlighting increased control, efficiency, and savings gained. Gather requirements and include the importance of adaptability, security, and risk mitigation.

- What does success look like?

- What risks should be considered and mitigated?

- Which use cases offer the right balance of value creation and time-to-value?

Step 3: Research and Select Your Solution(s)

Do the work. There are many solutions available, and it’s important to do your research. Narrow your potential solutions with key stakeholders.

- Will the solution provide the desired efficiency?

- Will it be able to support you in the future?

- Does the solution meet your requirements and business objectives?

Step 4: Design and Deploy the Solution(s)

Select an implementation partner and create the map that you’ll follow for a successful process. Once created and agreed on by your key stakeholders, begin deployment.

- Does the design fit your needs?

- Is there a timeline and achievable ROI?

- Have the key stakeholders reviewed and agreed on the plan?

Step 5: Manage Change and Drive Adoption

To effectively integrate the change that smart manufacturing will bring into your culture, you’ll need sponsorship, messaging, and accountability.

- Who will be your adoption champion(s)?

- What is your adoption communication/messaging plan?

- How will you adapt your culture through change management?

Kickstart Your Smart Manufacturing Journey

These five steps don’t offer all the answers but using them as a guide will help frame your approach to technology adoption. Remember to be thoughtful by setting and tracking goals. Each organization is different, and the points laid out here will help to ask the right questions in pursuit of answers that will guide your mission.